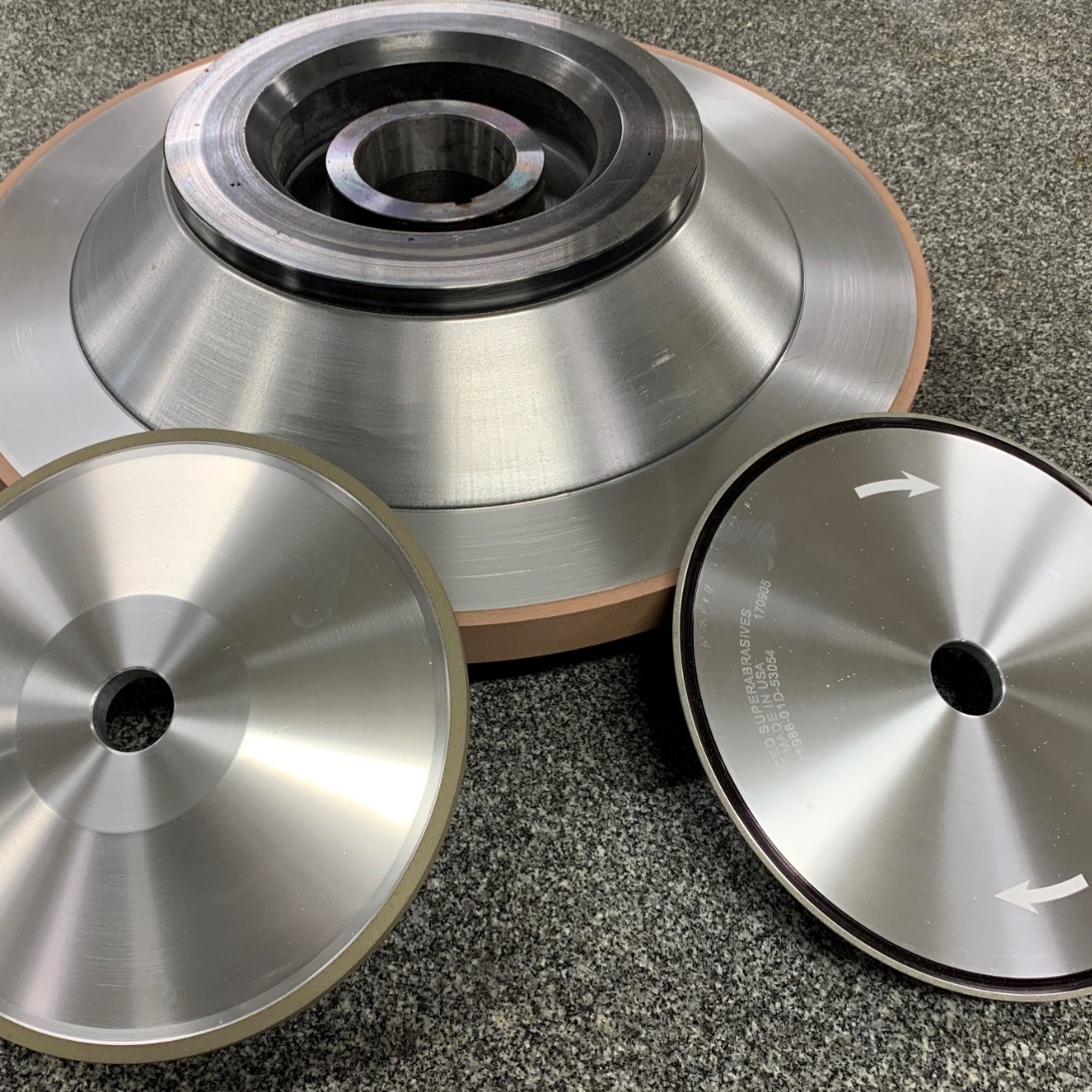

Advanced Superabrasives, Inc. stocks a variety of dressing wheels to keep your diamond and CBN grinding wheels sharp and free cutting for optimum efficiency. Our dressing wheels are made of aluminum oxide or silicon carbide, and vary in grit, hardness, and grain structure. We also provide heavy metal truing/dressing rods for centerless and surface grinding applications.

Our dressing wheels true the surface of a diamond or CBN grinding wheel by returning a wheel to its original round shape, removing burnt or compromised bond from the wheel, as well as to make a different profile on the diamond or CBN grinding wheel.

When choosing a dressing wheel, we suggest speaking with an Advanced Superabrasives, Inc. expert staff member because, if a dressing wheel is too soft or too hard, or the incorrect grit size, you may experience the following problems:

- Excessive dressing wheel wear

- Chatter

- Crystal pull out (ripping out the diamond or CBN crystals from the bond)

- Chipping or micro-chipping on the edge of the diamond / CBN wheel

- Runout in the diamond or CBN wheel introduced from the dressing wheel

When using our dressing wheels our customers will see the following benefits:

- Truing a diamond or CBN grinding wheel will make the wheel concentric to the bore (removing any runout on the OD of the wheel). This will improve surface finish and prevent burning.

- Truing will restore the roundness of a diamond and CBN grinding wheel, which will reduce vibration during grinding.

- It is necessary to use one of ASI’s dressing sticks after the truing operation to properly sharpen the wheel by exposing the diamond or CBN crystal.

If your company utilizes high quantities of dressing wheels, please ask about our Hold for Release agreement and/or Blanket Order agreement. These agreements can ensure that Advanced Superabrasives, Inc. will always have the specific dressing wheels you need on hand, ready to ship, which will decrease your lead times.

“Out of all the grinding wheel’s I’ve tried ASI’s have lasted longer.”

Scott Collins – Heacock Metal & Machine

You may also be interested in:

MT-30

Advanced Superabrasives, Inc. has designed and manufactures a Coolant Filtration System that quickly removes carbide, cermet, cast metals, glass and ceramic grinding particulates from oil and/or water based synthetic coolants.

Hybrid

Advanced Superabrasives, Inc.’s (ASI) Hybrid Diamond and CBN grinding wheels were engineered to improve our grinding wheel’s quality, consistentcy, and productivity output for our customers.

Resin Bond

ASI’s resin bond wheels are ideal for grinding hardened steel, tungsten carbide, PCD, PCBN, optical glass, ruby, ceramics and many other materials.