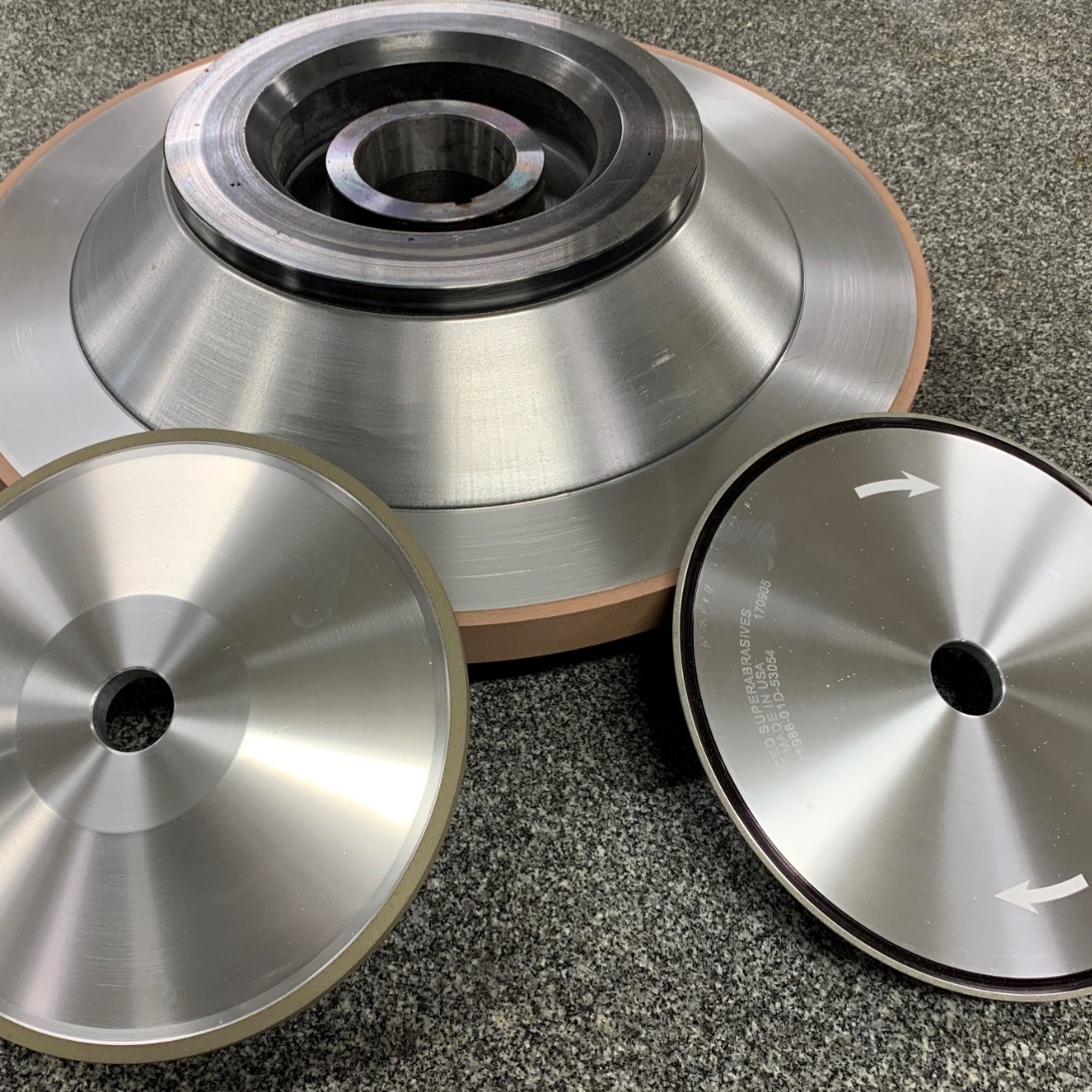

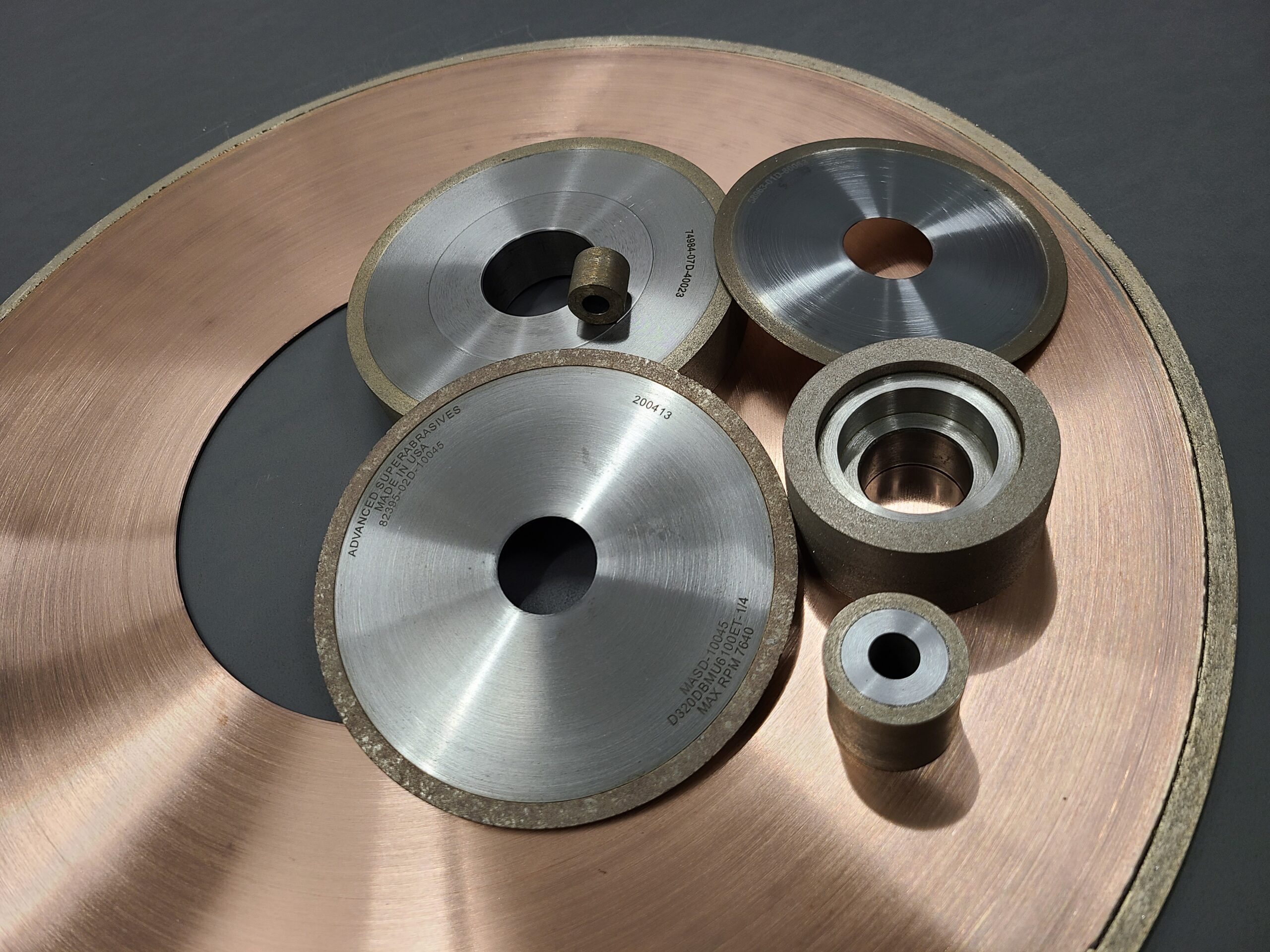

Advanced Superabrasives, Inc.’s (ASI) Metal Bond diamond and CBN grinding wheels are a great choice for your most aggressive grinding project.

These wheels hold their form better than conventional, resin, or polyimide bonds, all while still remaining free cutting.

Metal bond wheels can be utilized in wet or dry grinding applications. These wheels release heat through their metal binder and core, which is ideal for increasing material removal rates, and extends time between dressing and truing.

Usage Applications:

ASI’s Metal Bond Diamond & CBN Grinding wheels can be utilized in numerous grinding applications. These include but are not limited to:

- Surface Grinding

- Deep Cutting

- Glass Cutting

- Grooving

- Wet or Dry Grinding

- OD Grinding

- Cutoff

- Metal Working

“ASI is the most reliable grinding wheel company in the industry. The Owners of the company take a personal interest in our company, and the customer service is exemplary.”

Paul Settelmaier – VOLLMER OF AMERICA CORP

Metal Bond Grinding Wheels in Detail

Material Application:

Metal bond wheels can be utilized on multiple different material types. These include but are not limited to:

- Optical Glass

- Tungsten Carbide

- Steel (Stainless, and heat resistant)

- Ceramic

- Quartz

- Titanium Alloy

- Automotive Parts Manufacturing.

- Air Condition Parts Manufacturing.

Common Wheel Styles Used:

- 1A1

- 1V1

- 2A2T (Blanchard Style)

- 6A2 (Double Disc)

- 1E1

- 4BT9

Benefits:

Metal bond wheels provide the following benefits for our customers:

- Low maintenance

- More production output

- Extreme wear resistance

- Wheel sharpness is maintained longer

- Better heat transfer from the ground material

- Longer product life cycle

You may also be interested in:

Hybrid

Advanced Superabrasives, Inc.’s (ASI) Hybrid Diamond and CBN grinding wheels were engineered to improve our grinding wheel’s quality, consistentcy, and productivity output for our customers.

Resin Bond

ASI’s resin bond wheels are ideal for grinding hardened steel, tungsten carbide, PCD, PCBN, optical glass, ruby, ceramics and many other materials

MT-30

Advanced Superabrasives, Inc. has designed and manufactures a Coolant Filtration System that quickly removes carbide, cermet, cast metals, glass and ceramic grinding particulates from oil and/or water based synthetic coolants.